CRY2623M Fixed Acoustic Imager

Fixed acoustic imaging system for continuous monitoring and remote detection of leaks and partial discharges in industrial environments.

Product Overview

The CRY2623M Fixed Acoustic Imager uses microphone array beamforming technology to obtain sound source distribution data and works in conjunction with high-definition cameras to capture real-time video images.

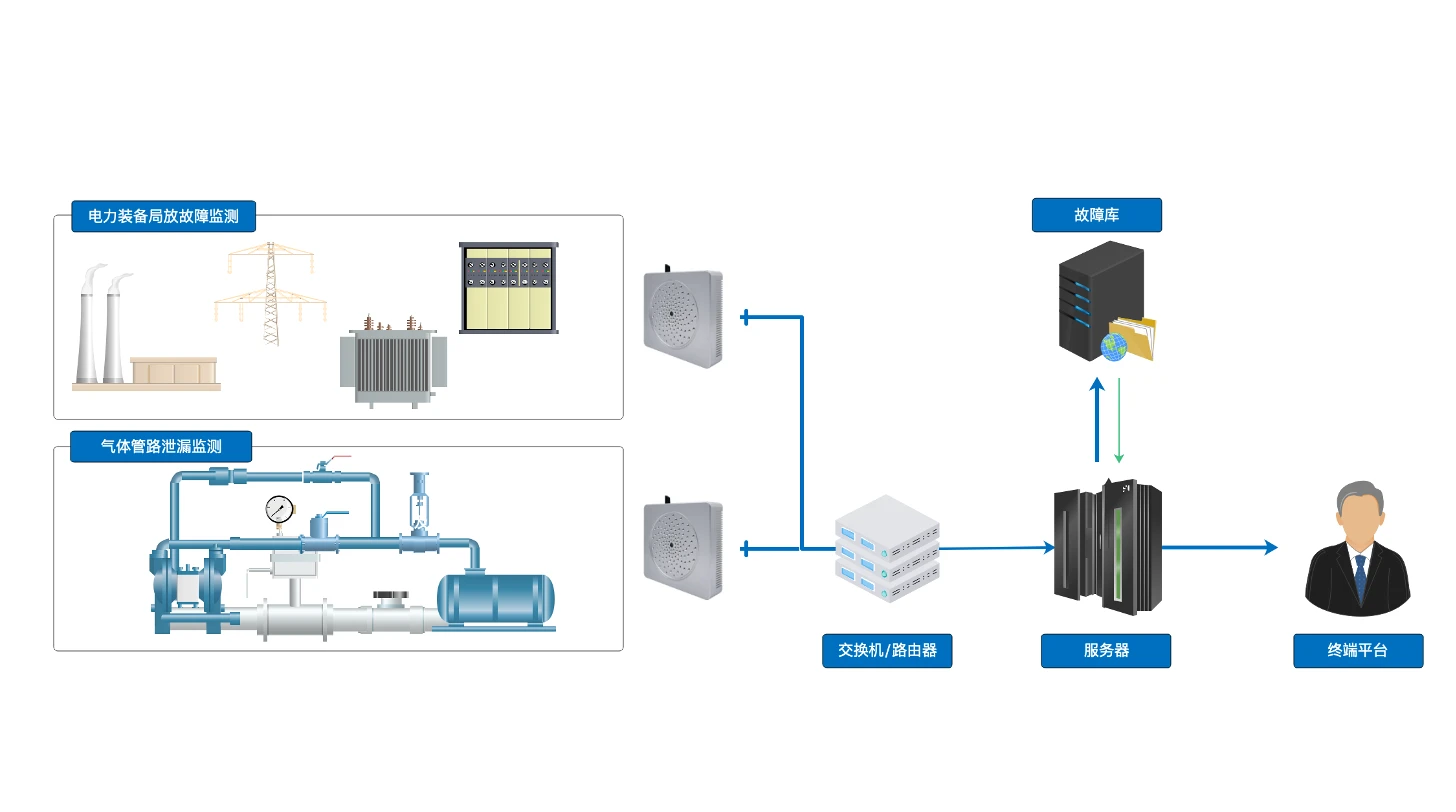

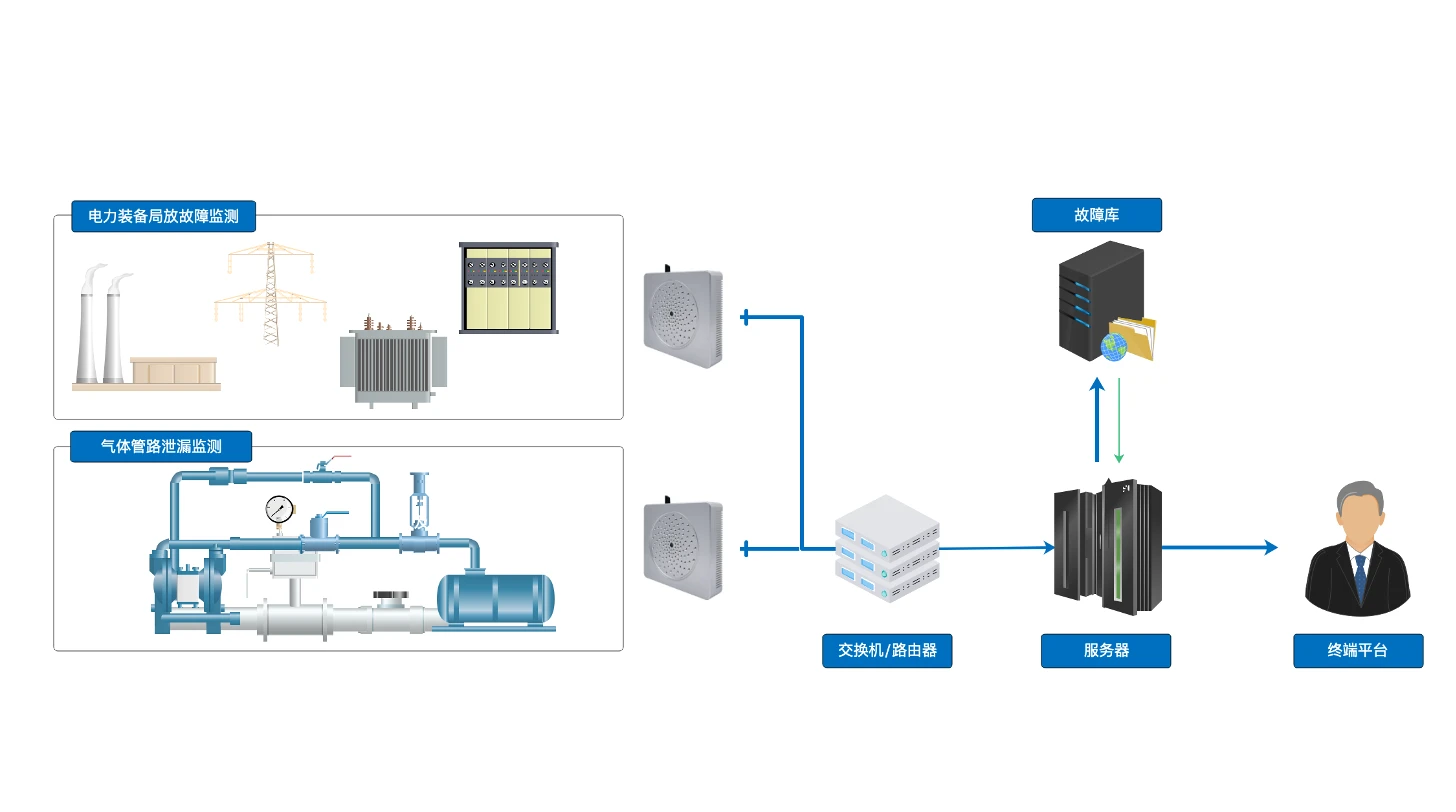

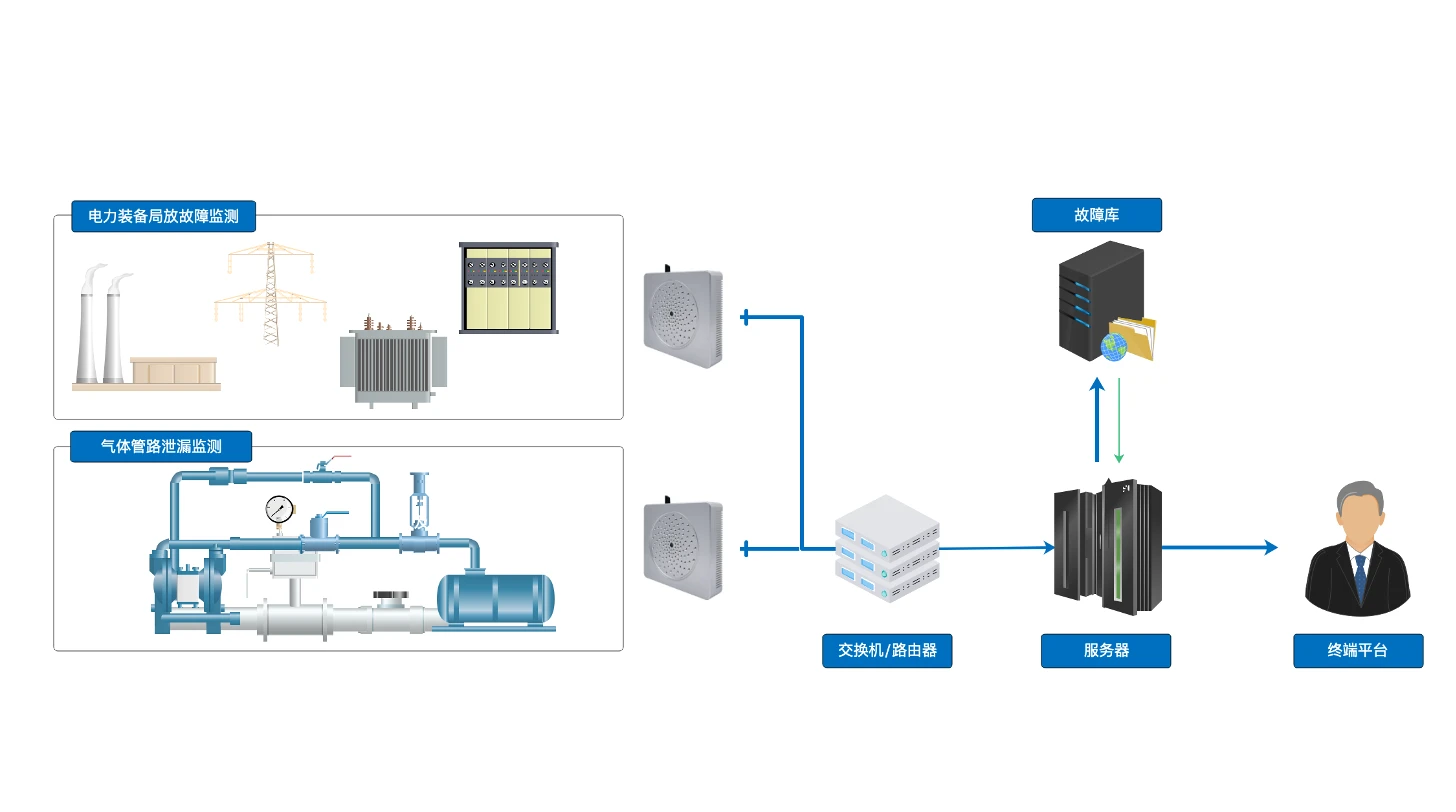

The system can assist users in implementing a remote monitoring system based on local area networks (LAN, etc.), wide area networks (WAN, ADSL, 4G, and private networks, etc.), aiding in industrial digital transformation and supporting real-time remote monitoring of video images.

This provides facilities with deeper insight into product quality or safety issues, as well as the ability to detect them quickly. Changes in compressors, pumps, pipelines, cables, etc. can be understood in real-time and in advance, rather than manually.

Key Features

The CRY2623M Fixed Acoustic Imager offers advanced features for continuous monitoring and early fault detection.

128 MEMS Microphones

Array of 128 digital MEMS microphones for precise and detailed capture of sound sources in industrial environments.

24/7 Monitoring

Continuous real-time monitoring, 24 hours a day, 7 days a week, for immediate fault detection.

Easy Installation

Compact size and optimized design for easy installation in various industrial environments.

Advanced Detection

Finds faults that cannot be detected by conventional methods, even in noisy environments.

Alarm System

Automatic alerts when anomalies are detected, allowing rapid intervention and prevention of major failures.

Remote Connectivity

Support for LAN, WAN, ADSL, 4G and private networks for real-time remote monitoring.

Usage Scenarios

The CRY2623M Fixed Acoustic Imager is ideal for various industrial scenarios that require continuous monitoring.

Hazardous Gas Areas

Priority areas containing hazardous gases, where early leak detection is crucial for safety.

Complex Piping

Key areas with high probability of failure in complex piping, difficult to monitor manually.

Hard-to-Reach Areas

Key testing areas that are difficult for inspectors to reach, reducing risks and operational costs.

Integrated Systems

The CRY2623M can be integrated into different systems to meet your operation's specific needs.

Smart Inspection System

Can be used as payload for inspection, including UAV, robot, car or other mobile unit, performing smarter inspection and monitoring applications.

Online Monitoring System

Fix the CRY2623M acoustic imaging module in certain key areas and achieve complete 24/7 fault monitoring and alarm. Provides accurate and real-time information about your equipment status and instant fault notification.

Product Overview

The CRY2623M Fixed Acoustic Imager uses microphone array beamforming technology to obtain sound source distribution data, and cooperates with high-definition cameras to capture real-time video images.

Software and Data Analysis

The CRY2623M comes with powerful analysis software for advanced data processing.

Software CRYSOUND

CRYSOUND software offers advanced tools for analysis and report generation, enabling deep understanding of collected acoustic data.

Report Types

- Gas/Electricity Reports

- ISO 50001 compatible reports

- Export in multiple formats

Analysis Types

- Waveform Analysis

- Spectrum Analysis

- Spectrograms

- Leak Assessment

- Discharge Type Discrimination

Application Gallery

See the CRY2623M Fixed Acoustic Imager in different application scenarios.

CRY2623M front view

CRY2623M microphone array

CRY2623M side view

CRY2623M mobile applications

Integrated monitoring system

CRY2623M front and back

Ready to revolutionize your industrial monitoring?

Contact us today for a demonstration of the CRY2623M Fixed Acoustic Imager and discover how it can help your company save time and resources.