CRY2623 Industrial Acoustic Imager

Fast and accurate detection of gas leaks and partial discharges in noisy industrial environments with state-of-the-art acoustic imaging technology.

Product Overview

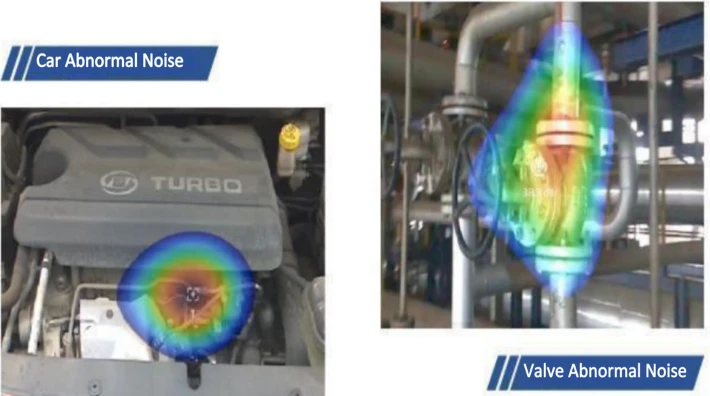

The CRY2623 is a portable industrial acoustic imager that supports ultrasonic frequency band. The instrument uses microphone array beamforming technology to acquire sound source distribution data and collects real-time video images with a high-definition camera.

By integrating sound source distribution data with video imaging, the changing sound source is dynamically displayed on the screen. The CRY2623 helps you quickly detect potential air, gas, and vacuum leakage failures in noisy industrial environments.

An electrical device with partial discharge failure is found in the power system. The industrial acoustic imager is built with an aluminum alloy housing, which is strong and durable, and can adapt to complex and changing work environments.

Main Applications

The CRY2623 is versatile and can be used in various industrial applications to detect problems before they become serious failures.

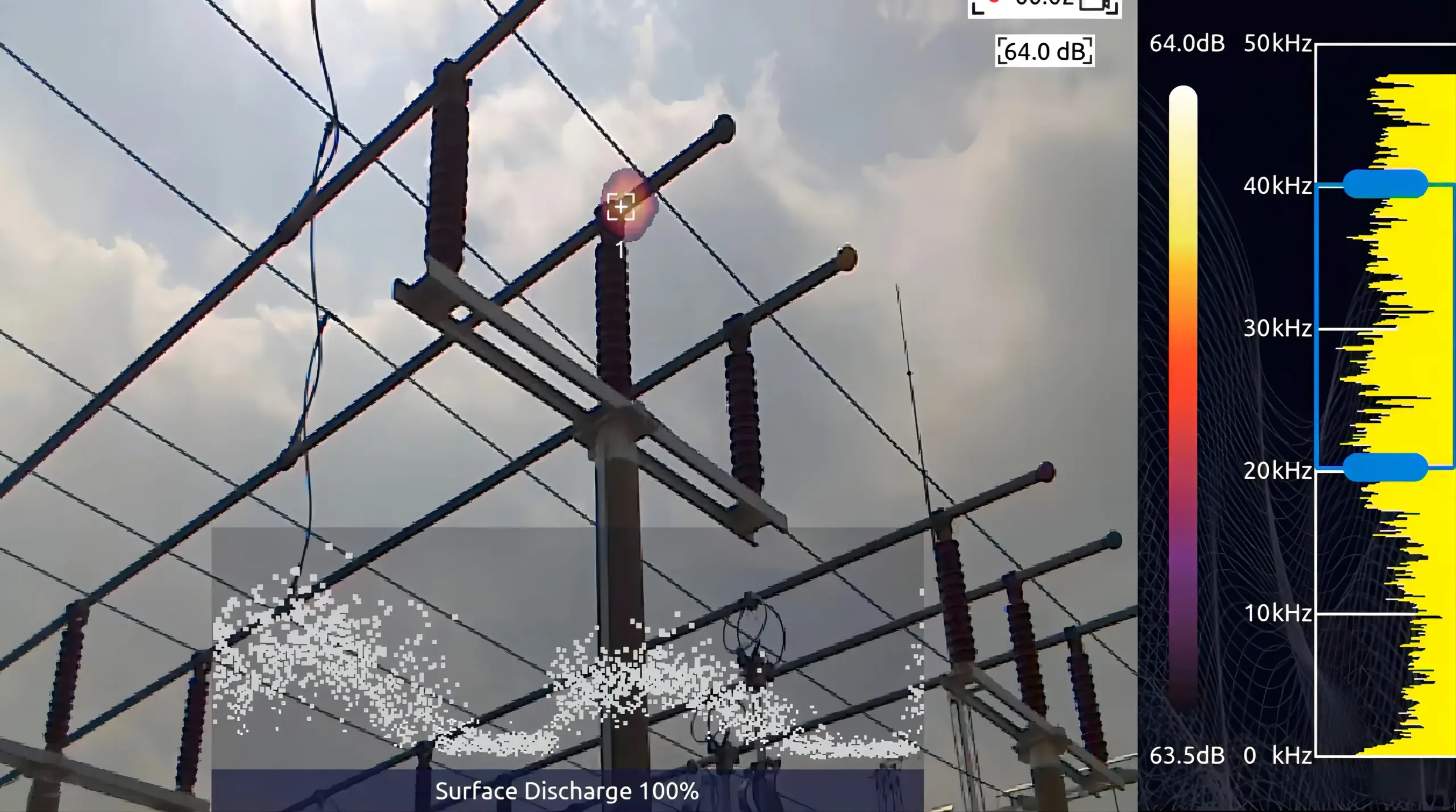

PD Detection

Partial discharges can be detected before more serious failures occur, even before a thermal camera detects them.

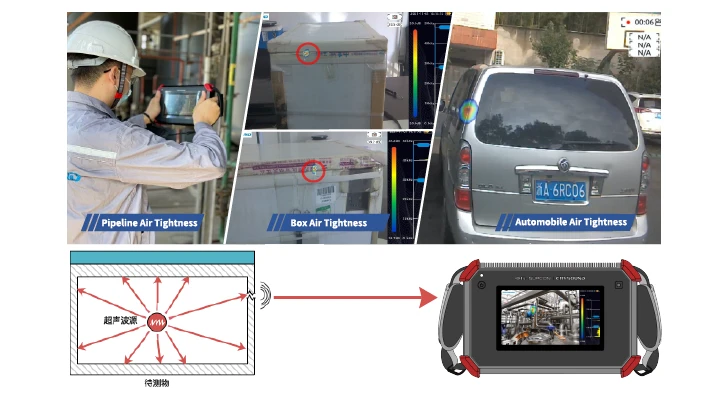

Leak Detection

When a leak occurs in any pressurized gas, the turbulence created by the gas flow emits acoustic energy that can be detected by the CRY2623.

Leak Test

The acoustic imaging leak detection method is highly efficient and does not cause damage to the object being measured, surpassing traditional methods.

Vacuum Leak

Detect leaks in vacuum and negative pressure systems with precision, even in industrial environments with high background noise.

Technical Specifications

Learn about the technical details of the CRY2623 Industrial Acoustic Imager.

Advanced Features

The CRY2623 offers advanced features to facilitate your inspection and diagnostic work.

Leak Assessment

When the leak measurement function is activated, the camera continuously displays the amount of leaks and losses, as well as the loss level.

Analysis and Reports

Processing and recording of data, waveforms, spectra, and model-based spectrograms are supported by the CRYSOUND report analysis software.

Simplified Operation

The CRY2623 only needs to adjust the two parameters of test frequency range and test dynamic range to meet the vast majority of test requirements.

Frequently Asked Questions

Answers to the most common questions about the CRY2623.

What is the difference between the CRY2623 and other acoustic detectors?

The CRY2623 uses microphone array beamforming technology to create real-time acoustic images, allowing precise visualization of the sound source. This differentiates it from simple acoustic detectors that only indicate the presence of sound without showing its exact location.

Can the CRY2623 be used in outdoor environments?

Yes, the CRY2623 is built with a resistant and durable aluminum alloy housing, designed to withstand complex and variable work environments, including outdoor use in industrial conditions.

What types of gases can the CRY2623 detect?

The CRY2623 can detect leaks from any pressurized gas or vacuum that creates turbulence when leaking. This includes compressed air, natural gas, hydrogen, helium, argon, nitrogen and many other industrial gases.

Is specialized training required to use the CRY2623?

The CRY2623 was designed to be intuitive and easy to use. Most users can learn to operate it effectively in a few hours. However, we offer comprehensive training to ensure that users make the most of all the equipment's features.

Ready to revolutionize your industrial inspections?

Contact us today for a demonstration of the CRY2623 Industrial Acoustic Imager and discover how it can help your company save time and resources.